Innovative safety control

Microbiological safety cabinets are used for operator, product, and environment protection when working with hazardous or potentially hazardous microorganisms. Traditional way of protection is creation of the barriers preventing circulation of the pathogens. For instance, a typical barrier would be a housing of the cabinet, filters, an air curtain in the work opening, and a laminar down flow in the work chamber.

Since air flow has the most unstable barrier characteristics, it requires incessant monitoring of the airflows’ velocity and interaction balance. Therefore all microbiological safety cabinets are supplied with sensors monitoring the airflows’ parameters. One of the most difficult solutions for each manufacturer is calibration of sensors installed since cabinet’s safety efficiency depends on sensor’s precise measurements.

LAMSYSTEMS engineers offered a systematic solution incorporating pressure sensors in the construction of the LAMSYSTEMS cabinets. It has obvious advantages in comparison with the hot-wire sensors usually used in the cabinets of such types. Pressure sensors are resistant to dust, humidity, and temperature changes. They keep indicated parameters precise during the whole period of exploitation without additional periodical adjustment. Calibration of the microprocessor control system is done only once during the manufacturing process by the special technique using the calibrator and the unique software.

When cabinet is used microprocessor control system processes data from pressure control points and runs them in a special algorithm. Distribution of the pressure control points has its own peculiarities and is a manufacturer’s know-how. It allows monitoring of airflow interactions with high-precision and minimal number of sensors installed.

Any, even minor, changes in velocity, direction or balance of the airflows causing drop in cabinet’s safety will be registered by the control system and will automatically trigger an audible alarm.

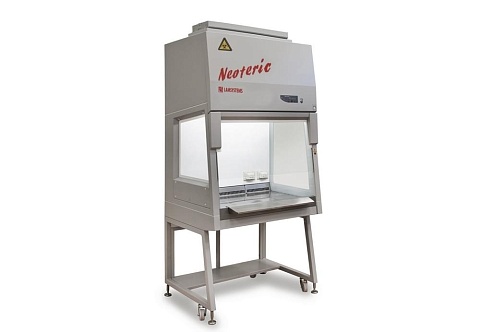

Innovative developments implemented in the microbiological safety cabinet class II NEOTERIC by the LAMSYSTEMS specialists guarantee high efficiency in protection of an operator, product, and environment when working with hazardous microorganisms and biological agents.