Company

LAMSYSTEMS is a private holding that produces specialized high-technology equipment for factories and laboratories that have strict requirements to the cleanliness of the air environment.

The company employs leading professionals that specialize in original technologies of manufacturing of precise products that conform to all the latest requirements to the equipment of laboratories, research centers, construction of clean rooms and clean zones in medical, pharmaceutical, microelectronics, food and other industries.

Products

The company manufactures microbiological safety cabinets, vertical laminar flow cabinets , PCR cabinets, fume hoods, sterile storage cabinets and customized equipment: clean zones и clean rooms.

One of the separate activities of the company is the production of technological apparel for clean rooms in medicine and manufacture, for work with microorganisms (anti-plague), antistatic, acid-resistant and medical clothing, personal protection equipment (PPE) and accessories.

The company is constantly upgrading its products developing and mastering the processes of manufacturing of new types and models of laboratory equipment and specialized clothing, introducing own unique designs as well as carrying out regular quality and usability enhancement works. Each manufactured item passes comprehensive quality control in accordance with the international standard requirements in order to ensure its conformance to reference parameters and operating characteristics.

Flagship products of the company, the microbiological cabinets of Class II have passed international certification verifying it conformance to the European standard EN 12469:2000.

Metal Sheet Cutting

Metal sheet cutting is carried out by accurate laser cutting machines MAZAK (Japan). Highly purified nitrogen produced by our own nitrogen adsorption system is used as an assist gas for cutting. Using chemically non-reactive nitrogen allows the following:

- protection of edges from oxidizing ensuring high-quality adhesion of the coating;

- minimization of costs of pre-painting treatment;

- minimization of combustion gas production and complete elimination of hazardous iron oxides (produced in the process of blowing away the molten with the nitrogen from the cutting zone; the fine iron particles are caught by the filtration system preventing any pollution of the environment);

- significant amelioration of the work conditions of the cutting machine operators.

Additionally, highly accurate machines are used at the blanking stage:

- CNC plate cutter (guillotine) MULTICUT ЕНТ (Germany)

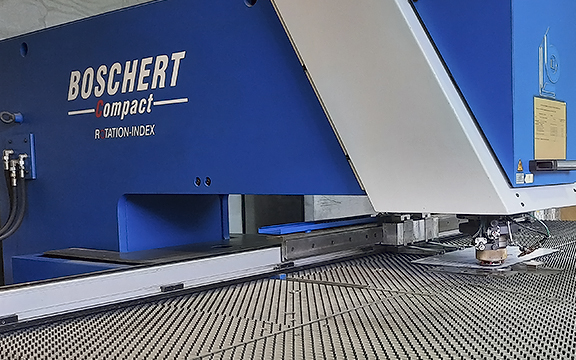

- punching machine BOSCHERT (Germany)

- CNC semi-automatic double mitre-cut bandsaw MEBA (Germany)

- multifunction mill turn centers DOOSAN (Korea)

Bending

The metal sheet bending is carried out by EHT VARIOPRESS (Germany) bending machines. The highly precise benders are featured with additional bending angle control devices that ensure high repeating accuracy and, consequently, precise assembly process.

Welding

Non-consumable gas-shielding (argon) welding is carried out using the advanced welding equipment that ensures high-quality welds and minimizes the production of welding aerosols. Each welding station is equipped with an electrostatic filtration unit built into the workshop exhaust system that minimizes the emission of the welding aerosols into the environment and reduces harmful impact on the operator’s work conditions.

Grinding

Grinding is carried out at special grinding tables equipped with exhaust and filtration system that catches the abrasive and metal dust preventing any pollution of the environment. The grinding station is equipped with specialized air supply system that ensures continuous laminar flow of the clean air into the work zone creating comfortable operating conditions for the personnel. Grinding machines featured with filtration systems are also used for part grinding.

Acceptance Testing

The acceptance testing workshop is equipped with advanced testing devices featured with automatic measurement result registration. The acceptance testing site is designed as a clean room of ISO 7 cleanliness class in accordance with ISO 14644-1 ensuring the required environment for testing as per reference documentation.

Scientific Cooperation

The specialists of the company are actively cooperating with the leading antiplague institutes. The Annual Science and Technology Conference organized by our company gathers the leading state representatives of antiplague and virologic research institutes. The main target of such cooperation is the collaborative research on personnel safety when working with pathogens and microorganisms, the development of guidelines, norms, practices and methods of safe work as well as the practice of equipment qualification and testing methods.

In collaboration with the Association of Engineers for Microcontamination Control (ASENMCO), LAMSYSTEMS specialists initiated development and introduction of the Russian standard GOST R EN 12469-2010 that is a direct translation of the European standard EN 12469:2000 Biotechnology. Performance criteria for microbiological safety cabinets.