Laminar Flow Hoods: Types and Application

Laminar air flow hoods, or cabinets (also called tissue culture hoods), are accurately enclosed laboratory benches that are used to prevent biological substances, semiconductors and other particle-sensitive substances in labs from getting contaminated by delivering HEPA-filtered air.

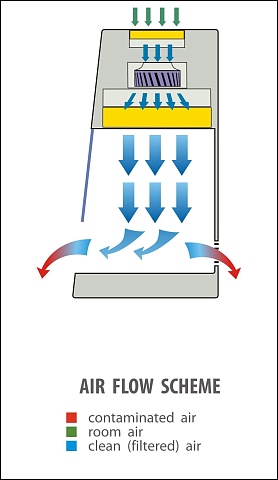

There is little to no cross-over of air flows that would move particles around; a laminar flow hood simply moves the particles in one direction straight out of the enclosed area. However, it should be noted, that, because of the direction of laminar air flow, the hoods do not protect the lab worker from infection and contamination.

Types of Laminar Flow Hoods

In general, cabinets are made of steel. It is very important that these hoods have no joints and gaps, because this is where bacteria can collect and cause contamination. There are both vertical and horizontal types of such laboratory benches, and many other configurations with various parameters are used in modern labs. Nonetheless, all laminar flow cabinets have one thing in common: they use laminar airflow to help maintain sterility, decrease turbulence and prevent the operating environment from contamination.

A clean bench and a biosafety cabinet (BSC) are typical examples of a laminar air flow cabinet.

Variations in Laminar Flow Hoods

Laminar flow hoods can differ based on the air movement. Other key differences include:

- Intended use

- Sterility

The main configurations are vertical and horizontal. Below are the defining characteristics of each type of cabinet.

Vertical Laminar Flow Cabinet

- Upright air circulation

- Operating zone positioned underneath

- Overhead filtration units

- Specimen protection

Example of usage: biological research, microelectronics, pharmaceutical and food industries.

Vertical laminar flow cabinets are better for preserving specimen sterility and purity.

Horizontal Laminar Flow Cabinet

- Lateral air circulation

- Filtration systems at the rear

- Higher human exposure risk

- Operations performed within a lateral airstream

Example of usage: electronics assembly, pharmaceutical prep, and some laboratory work.

Horizontal laminar flow cabinets are better for situations requiring easy access to materials.

Based on the information above, you can choose which type is best suited to your lab.

What Are the Elements of a Laminar Flow Hood?

- Body. It provides isolation of the internal environment created within the laminar airflow hood and prevents it from external environment influences.

- Tabletop. Inside the cabinet, there is a flat workstation for all the processes.

- HEPA filter. Inside the cabinet, there is a HEPA filter, which is a mechanical air filter that disinfects the operating environment. This filter does not let the air pass through microbes, smoke and dust, providing sterility and minimizing the risk of contamination.

- Laminarization screen. A laminarizer produces distributed air flow.

- Fan. It is placed above the filter mat that sucks in the air and moves it all around in the cabinet.

- Ultraviolet lamp. It sterilizes the inside of the hood and its elements before use.

- Fluorescent or LED lamp. It provides proper light while working.

What Are the Precautions Needed When Using a Laminar Flow Hood?

Before using a laminar air flow hood for the first time, it is absolutely essential to refer to the manual first, read the instructions carefully and follow the precautions listed below:

- Make sure the laminar airflow hood gets disinfected and decontaminated with the help of the ultraviolet (UV) lamp before and after use

- Make sure that the workstation, glass side wall and the rest of the internal parts of the laminar flow hood are disinfected and decontaminated before and after work

- Do not use the ultraviolet lamp and airflow simultaneously

- Do not perform any operations when the ultraviolet light is on

- Always wear a white coat (laboratory coat) and long gloves while working with dangerous materials.

Applications Of Laminar Flow Hoods

Laminar flow hoods are suitable for various applications. The cabinets can be adapted to the specific requirements of the laboratory and are also ideal for general laboratory work, especially in the medical, pharmaceutical, electronic, and industrial sectors.

Laminar flow cabinets are used in all industries with high air purity requirements. This equipment can be placed inside existing cleanrooms and clean areas to create local workplaces of higher purity class. Installed in a row, laminar flow cabinets allow you to create a single assembly line. The box is designed to protect the product (including cross-contamination) and remove contamination during operation by displacing air from the box. This is achieved by creating a downward unidirectional air flow inside the box.

The applications for laminar enclosures are varied. Let us consider some examples.

- Class II, Type A cabinets, if there is no connection to the canopy, transfer the purified air back to the laboratory.

- Class II, Type B cabinets give hard ventilation to the outside.

- Class II, Type C1 cabinets can do both.

- PCR stations - cabinets for polymerase chain reaction experiments - use vertical airflow with HEPA filtration. A UV lamp is needed for the denaturation of genetic material (DNA, RNA, etc.) and secondary disinfection. This is done to ensure that there is no particulate matter in the work environment.

- Clean benches are suitable for preparing media plates or serving tissue culture. The air drawn from the outside is first pre-filtered and then HEPA filtered.

- In the vertical clean bench, the laminar air is directed vertically and in the horizontal clean bench, respectively, horizontally toward the operator.