What Is Laminar Flow?

Laminar flow is described as a fluid (gas or liquid) flowing in layers, which tends to happen when there are minimal disturbances. It is characterized by uniformity in both velocity and direction. It is often contrasted to turbulent flow when the fluid swirls and blends when moving along a confined space.

The mechanism of the laminar flow was developed in the early 1960s. This advancement has made its way to modern labs and has been utilized for laboratory enclosures. Since laminar flows can safely move the fluids in a straight, smooth pipe, this characteristic is used to ensure an operative area devoid of contaminants.

What Is a Laminar Flow Hood?

A laminar flow hood is a special device, i.e. an enclosed bench, made to prevent particulate contamination. It solves the issue with contamination-sensitive spaces using the following laminar flow hood working principle: laminar flow passes particles from the under-the-hood area (the filter face) to the back or bottom of the hood (sash opening), which is the exit area.

Laminar flow hoods can be tailor-made to meet specific laboratory needs, and they are suitable for general lab work as well. But the overall design and construction remain the same: these chambers are made from high-quality materials with no gaps or joints. There is no bacteria build-up from any samples since the design makes it easier to clean and disinfect. Also, it is important to note that it keeps samples protected from outside contamination but operators will have some exposure to the contents of it.

Laminar flow cabinets can be used in many industries. They can be dedicated to an unlimited variety of tasks, yet the primary function remains the same – creating a particle-free operating space and ensure sample sterility. Some examples of the most common uses include:

- Pharmaceuticals: compounding of non-hazardous drugs, preparing injection solutions;

- Medical: microscopy, pipetting tasks;

- Manufacturing and food processing: product runs, mechanism assembly, quality control;

- Scientific research fields: comprising cell culture media, polymerase chain reaction (PCR) setup;

- Environmental: an examination of biological samples, control experiments, and a lot more.

Horizontal vs. Vertical Laminar Flow Hoods

There are two laminar airflow hood types, which differ by the direction of the air movement. The first one sweeps airflow vertically and is called a vertical laminar flow hood. The other does so horizontally. There are compelling arguments for either principle, and the choice is mainly contingent on conditions for clearance, type of laboratory, safety standards for an operator, and lab work surfaces. Using different laminar air flow patterns, both configurations have unique benefits and suit specific applications.

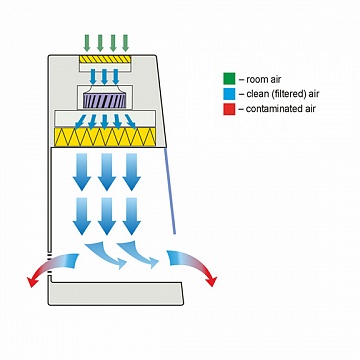

Vertical Laminar Flow Hood Diagram

A vertical laminar flow system directs the vertical laminar flow into a downward filter located on top of the working chamber above the operative surface. It emphasizes gravitational impact and moves the flow via the front access area to remove the particles. The mass of emerging contaminants (ECs) or micro-pollutants is not always sufficient. The vast majority of particles are removed from the box with the help of the airflow, and some of them land on the enclosure surfaces that can easily be disinfected.

In terms of design, a vertical laminar flow hood resembles a cleanroom, which also places the filtering component on the upper side. The main benefit, which is an essential factor for some labs, is that it does not take up considerable floor space.

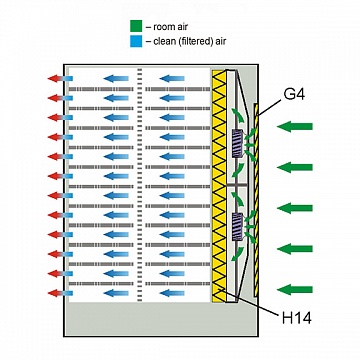

Horizontal Laminar Flow Hood Diagram

By the same token, these laminar flow hoods get their name due to the direction of airflow in the enclosed mechanism. Technically, the flow starts moving from above, similar to the vertical laminar hoods, but it quickly shifts and moves in the back-to-front direction across the functional surface. In some cases, the air intake is carried out from the side. Both methods protect material and product using a horizontal flow principle.

Pros and Cons of Vertical Laminar Flow Hoods

Pros

- Less space is needed because the hood is not as deep

- Air does not blow directly on the operator thanks to the sash, which makes a barrier

- The position of the filter on top makes it easier to reach

- Much less turbulent effect when the air hits large objects or process equipment

Cons

- Due to the location of the filter, space is needed above the hood

- One cannot place objects on top of each other to avoid interfering with the vertical airflow

Pros and Cons of Horizontal Laminar Flow Hoods

Pros

- Air flow is parallel to the work surface and reduces the turbulent effect

- Equipment can be positioned closer to the filter surface

- Employee's hands are less dirty because they are lower in the airflow

Cons

- Need access to the hood from behind for filter maintenance or replacement

- Samples that are too large can obstruct air flow and contaminate neighboring samples

- If the hood is used without a flap, fumes can get in the employee's face