Biosafety Cabinets

A Biological Safety Cabinet (BSC) is used in laboratories to facilitate safe work with harmful and contaminated particles and components. A Biosafety Cabinet ensures clean air intake and extraction to maintain a safe environment for staff. The downward airflow enters via a HEPA filter with high bacterial purification efficiency, establishing a secure and disinfected operating zone that allows for particle examination.

Biosafety Cabinets Сlass II is for physical isolation of pathogenic biological agents and microorganisms to prevent airborne infection of the staff and contamination of the air in the working room and to protect the environment.

Class II Type B2 Biosafety Cabinet ensures environment, product, and personal protection during lab procedures where the circulation of filtered air is restricted due to the existence of possible chemical fumes that are released during the process.

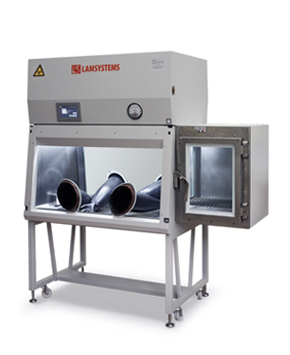

The Class III Biosafety Cabinet is designed to work best with risk group 4 microorganisms.The Class 3 Biological Safety Cabinets are also called Gloveboxes, due to work being conducted using arm-length gloves.

Exhaust air is released from the Biological Safety Cabinet via another HEPA filter, preventing atmospheric contamination. This equipment safeguards personnel and the atmosphere. Our selection of microbiological safety cabinets features different products with diverse specifications, custom-designed options, and intuitive management features. Biological safety cabinets include components that are required to perform different types of work. These include armrests, electric sockets, UV lamps as well as various additional options that the cabinet can be featured with.

The microbiological safety cabinets were examined and tested based on two international standards, EN 12469:2000. These certificates confirm the safety and performance of this apparatus, meaning it will protect staff and the atmosphere from contaminated air and materials.

Euro Standard EN12469

The EU standard EN 12469. This classifies the equipment into three categories.

NSF Standard Classification

The first Biological Safety Cabinets were created in the 20th century, and standards were set by the Center for Disease Control (CDC), the National Institutes of Health (NIH), and the National Cancer Institute (NCI). According to these standards, the equipment is divided into types based on air movement. Class II Biosafety supplies are subdivided into Class II Type A1, A2, B1, and B2.