Main purpose of the clean zones

- Maintenance of the air environment’s indicated parameters in a local work area;

- Product protection from the outward influences.

- Parameters of the air environment maintained in the working area depend on the technological process performed in the clean zone; however, as a rule there is one parameter – air cleanliness (both microbiological and from mechanical particles).

Application area

Clean zones are used in all manufacturing areas with high requirements to the air cleanliness, for example in pharmaceutics, perfume and cosmetics production, food production, etc.

TYPES OF CLEAN ZONES

Configurations

with a mandatory verification of filters being hermetically sealed after moving.

Clean zones can be produced stationary when their structures are fixed rigidly on the floor, walls, ceiling and other load-bearing structures of the room.

Benefits of the clean zones

- A clean zone may be used inside a clean room as well as in a regular room.

- Small size of the zones allows locating them in any type of a room.

- Regarding the air cleanliness level, the clean zones match with the clean rooms; however the zones are more cost-effective solution.

- Clean zones are mobile – they can be used where needed at the moment (modular demountable construction).

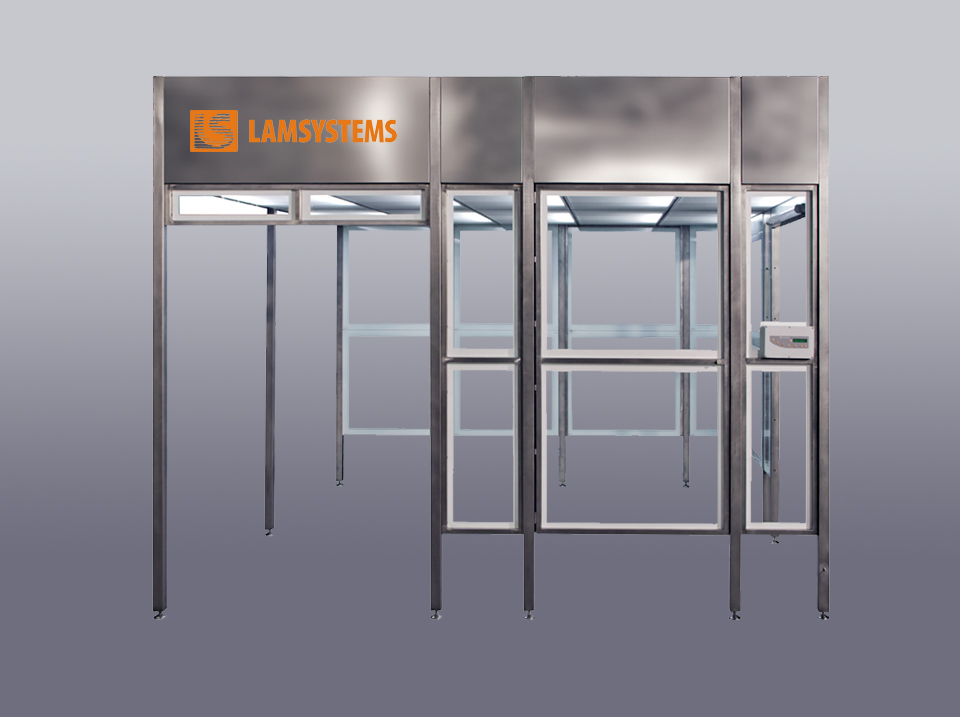

Photos of Completed Projects

Clean Zone Qualification

The mandatory installation qualification (validation) of clean rooms and clean zones is carried out in cooperation of a Customer’s representative and the authorized Lamsystems specialists that have passed the specialized training as well as have extensive experience of electronics, optical mechanics and aerospace industry clean room and clean zone qualification.

Lamsystems specialists have all the measuring devices and equipment required for qualification. Upon completion of the testing and checks, acceptance test reports and qualification protocols are issued.

These documents become part of the Customer’s documentation on the facility production process qualification and can be used for development of corrective measures in case the parameters of the equipment installed in the clean zone do not correspond to the cleanliness requirements.

The final stage of the procedure includes the training and consulting of the Customer’s service personnel on the operation and work inside the clean zone.

- Checking the functioning and operation of the clean zone (clean room) in accordance with the Manual description.

- Checking the installed HEPA filters and their sealing integrity

- Checking the clean zone operating capacity for clean air downflow and air exchange rate

- Checking the specified air cleanliness class in the work zone as per ISO 14644-1