FUME HOOD SHV-1,5-“Laminar-S.” with UV unit

Fume Hood SHV-1,5-“Laminar-S.” is designed for environment and operator protection when working with hazardous substances.

Application of the fume hoods

- Removes chemically harmful and low-toxic materials from the working zone providing operator’s protection in laboratories with different profiles;

- Fume hoods are designed to be used as part of the external exhaust system in clinical, diagnostic, dental, and other laboratories, medical organizations, food production and other industries.

-

Fume hoods are used for studies and works causing and spreading toxic vapors and gases harmful to human health and for work with materials that require quick elimination of accessory substances from the operating area.

- Fume hoods are not to be used with hazardous and potentially hazardous pathogenic agents and

FUME HOOD SHV-1,5-“Laminar-S.” with UV unit

Fume Hood SHV-1,5-“Laminar-S.” is designed for environment and operator protection when working with hazardous substances.

Application of the fume hoods

- Removes chemically harmful and low-toxic materials from the working zone providing operator’s protection in laboratories with different profiles;

- Fume hoods are designed to be used as part of the external exhaust system in clinical, diagnostic, dental, and other laboratories, medical organizations, food production and other industries.

-

Fume hoods are used for studies and works causing and spreading toxic vapors and gases harmful to human health and for work with materials that require quick elimination of accessory substances from the operating area.

- Fume hoods are not to be used with hazardous and potentially hazardous pathogenic agents and

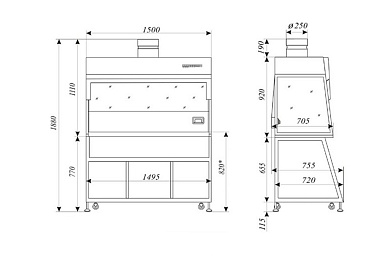

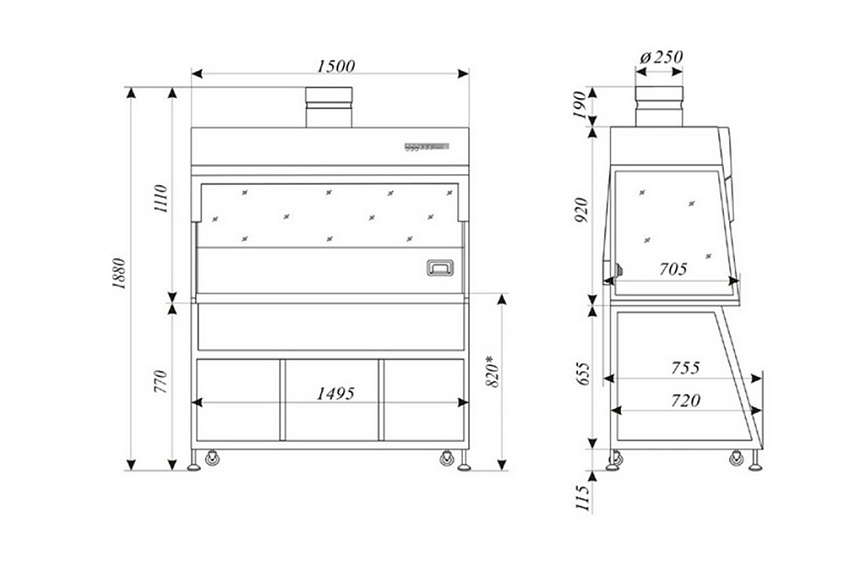

Main parameters and dimensions

FUME HOOD SHV-1,5-“Laminar-S.” with UV unit

| Article | 1Е-E.002-15.0 |

| Dimensions of the assembled cabinet with stand, mm (WхDхH) | 1500х770х1880 |

| Dimensions of the work chamber, mm (WхDхH) | 1500х710х1110 |

| Mass of assembled cabinet with the stand, kg, not more than | 126 |

| Input power of the cabinet, W, not more than (exclusively of the load on the built-in outlets) | 85 |

| Input power of the fan, W, not more than | 27 |

| Maximum load allowed on the sockets, W | 1000 |

| Luminance level in the working zone, lux, not less than | 1000 |

| Noise level at the 1 m distance from the cabinet, dB, not more than | 55 |

| Airflow outflow volume, m3/hr, not less than | 450 * |

* For maintenance of the average speed of the air inflow through the work opening on the level not less than 0.5 m/s the cabinet must be connected to the active exhaust system with a flow rate production not less than 885 m3/h.

Dimensional drawing

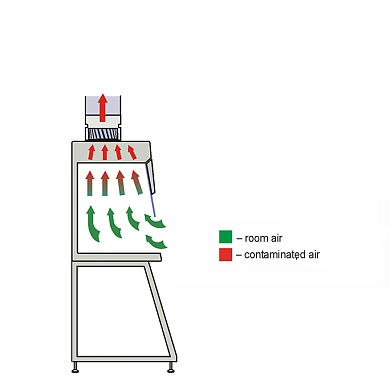

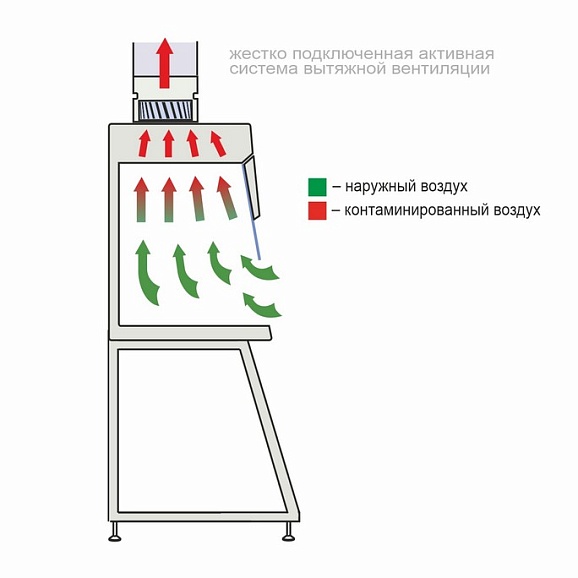

Air flow scheme

Standard Configuration

Work Chamber:

- Front sash is hinged, made of tempered glass; opening/closing mechanism is gas springs;

- Metal side walls;

- Luminance of the work chamber;

- Sockets unit inside the work chamber;

- Stainless steel tabletop

UV-unit

- UV unit located on the rear wall of the work chamber

Air exhaust elements

- Auxiliary blower;

- Back-flow valve with connecting flange to the exhaust system Ø 250 mm;

- Goffered metal hose Ø 250 mm, length 3 meters;

- 2 quick-release pipe bridges for metal hose attachment.

Control system elements

- Highlighted keyswitch for switching on/off the power to the cabinet, for switching on/off the lighting, for switching on/off the fan.

- UV control unit is equipped with anti-vandal buttons and timer with display with seven segments.

Support

- Frame stand is equipped with foot rest;

- Transporting wheels are designed for moving the cabinet with the stand;

- Screw supports are designed for stationary placement of the cabinet at the exploitation sight.