BMB-III-"Laminar-S."-1,2 PROTECT CLASS III

The model design allows using those cabinets for work with deadly bacteria and viruses.

Reduction of risk of infection of an operator working with airborne pathogenic agents and microorganisms, protection of the environment as well as the product from external contamination and cross-contamination.

If connected to the individual active exhaust system, the cabinet could be used for protection from small amounts of toxic chemical substances and radionuclides.

The system of monitoring with the audio-visible indication system warns operator about the failure of working modes in the cabinet.

Key Benefits

- The cabinet has a sealed PASS-THROUGH SLUICE GATE made of stainless steel.

- A PULL OUT SLUICE TABLE TOP makes loading objects into the working chamber easier.

- FRONT SASH can be lifted for equipment loading. It is made of laminated safety glass and equipped with two oval glove ports.

- REMOVABLE OUTLET UNIT in the working chamber with self-powered shutoff function.

- The design of the cabinet allows integrating several cabinets in one line for continuous technological process.

Additional options

BMB-III-"Laminar-S."-1,2 PROTECT CLASS III

The model design allows using those cabinets for work with deadly bacteria and viruses.

Reduction of risk of infection of an operator working with airborne pathogenic agents and microorganisms, protection of the environment as well as the product from external contamination and cross-contamination.

If connected to the individual active exhaust system, the cabinet could be used for protection from small amounts of toxic chemical substances and radionuclides.

The system of monitoring with the audio-visible indication system warns operator about the failure of working modes in the cabinet.

Key Benefits

- The cabinet has a sealed PASS-THROUGH SLUICE GATE made of stainless steel.

- A PULL OUT SLUICE TABLE TOP makes loading objects into the working chamber easier.

- FRONT SASH can be lifted for equipment loading. It is made of laminated safety glass and equipped with two oval glove ports.

- REMOVABLE OUTLET UNIT in the working chamber with self-powered shutoff function.

- The design of the cabinet allows integrating several cabinets in one line for continuous technological process.

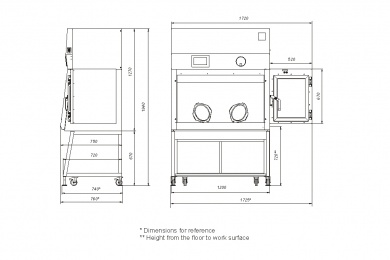

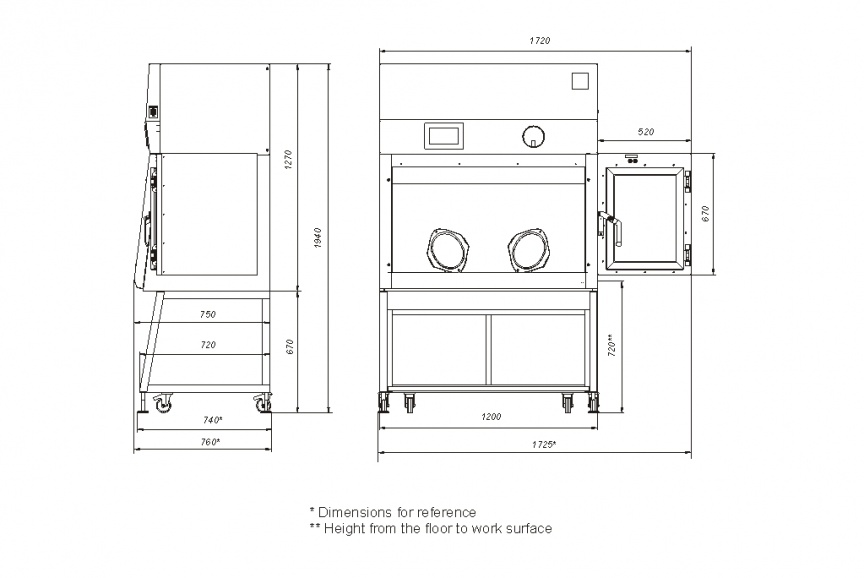

Main parameters and dimensions

Microbiological safety cabinet BMB-III-"Laminar-S."-1,2 PROTECT Class III

Main Parameters and Dimensions

| Article | 2E-C.001-12 |

| Dimensions of the cabinet with the pass box* (WxDxH), mm | 1720х750х1940 |

| Dimensions of the working chamber (WxDxH), mm | 1140х640х675 |

| Weight of the cabinet (net), kg, not more than | 350 |

| Power consumption (without the built-in outlets load), W, not more than | 420 |

| Maximum input power of the cabinet, W | 1420 |

* dimensions do not account for outstanding supports

Main characteristics

| Installation work chamber air cleanliness class for suspended particle (aerosol) concentration as per ISO 14644-1 | |

| -for particles of 0.5µm and more | ISO 5 |

| -for particles of 5.0µm and more | ISO M (20; ≥5µm); LSAPC |

| Cabinet class according to ЕN 12469, NSF/ANSI 49 | III |

| Class of the installed НЕРА-filters according to EN 1822-1 | H14 |

| Prefilter Class according to EN 779 | G4 |

| Minimal negative pressure in the working chamber, Pa, not less than | 200 |

| Permanently provided working negative pressure in the working chamber, Pa, not less than | 250 |

| Airflow rate through the supply HEPA filter, m3/h, not less than | 270-320 |

| Air inflow filtering | two-stage (G4, H14) |

| Air outflow filtering | two-stage (Н14, H14) |

| Illuminance level in the working zone, lux, not less than | 1500 |

| Air recirculation rate in the cabinet, % | no recirculation |

| Noise level at 1m distance from the cabinet, dB, not more than | 56* |

* in operating mode (fans and lighting turned on) in testing laboratory environment

Dimensional drawing

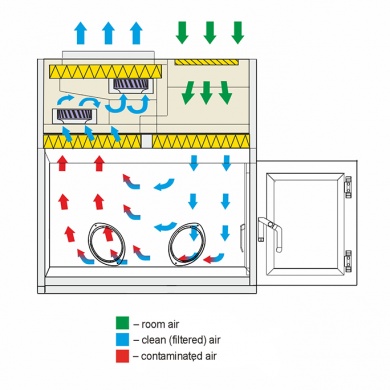

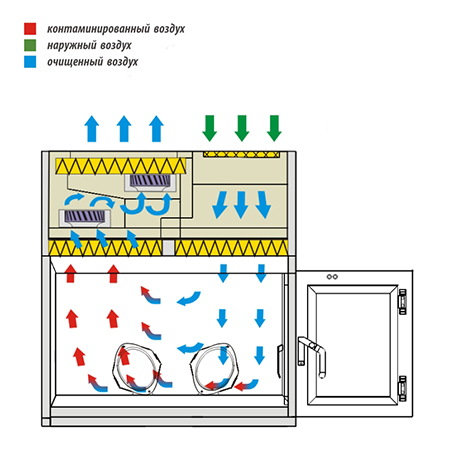

Air flow scheme

Standard Configuration

WorkChamber

- work chamber is made of stainless steel AISI 304;

- hinged front sash made of laminated safety glass resistant to UV and disinfectants;

- front window has two oval-shaped glove ports; the glove ports are featured with catches and guides for self-contained glove integrity testing module (not part of the delivery set; can be supplied as an additional option – article 0.15);

- each glove port is equipped with a chamber glove with silicon O-ring.

- 10-liter liquid-collecting tray made of stainless steel AISI 304 without drain located in the bottom part of the work chamber;

- LED lighting of the work chamber;

- two removable electric sockets in the work chamber (at the center of the junction of the tray and the rear wall);

- UV light in the work chamber;

- pressure gauge from -500 Pa to +500 Pa.

Supply and Exhaust Air Filtration System

- two-stage filtration of the air coming into the work chamber: prefilter G4 and supply HEPA filter H14 located over the work chamber;

- two-stage filtration of the exhaust air coming out of the cabinet: two successive exhaust HEPA filters H14;

- two fans ensuring air exhaust from the work chamber.

Pass Box

- outer panels of the pass box are made of powder-coated metal;

- inner chamber is leak-tight and made of stainless steel AISI 304;

- corner door location: the outer door in front of the cabinet, the inner door built into the side wall of the work chamber;

- pass box doors a equipped with handles made of stainless steel AISI 321;

- pass box doors are featured with electromechanical interlocks for preventing simultaneous opening of both of the doors;

- door windows are made of tempered glass;

- two UV lamps;

- LED lighting;

- pullout perforated tray made of stainless steel AISI 304 ensures simple transferring of objects from the pass box into the work chamber and UV irradiation of the bottom of the transferred materials.

Control System Components

- microprocessor control system;

- touchscreen control panel;

- pass box control panel is pushbutton with door and lock position indication;

- airflow sensors*;

- built-in power cord;

- individual fuse for fans and removable electric sockets;

- power switch for the removable electric sockets installed in the work chamber.

Airflow Adjustment Components

- adjusting baffle.

Additional Components

- caster wheels for cabinet relocation;

- screw supports for cabinet fixation at operating site;

- frame stand with footrest;

- perforated protection cover of the exhaust HEPA filter;

HEPA Filter Testing

- built-in air-sampling outlets for testing the HEPA filters.

Additional options