Laminar Flow Hoods VS. Biological Safety Cabinets

The choice between laminar flow hoods and biosafety cabinets depends on what you are aiming to protect: the product, the user, the environment, or a combination of all three. So, once you establish this objective, you will better understand what kind of machine is applicable to you.

You will also need to figure out future applications of the equipment, rules for contamination, and how much harm it could potentially cause to human health and the environment. Operations dealing with hazardous agents should be conducted according to appropriate safety requirements. For example, some tasks may be perfect for laminar flow hoods, while infectious agents would require a different approach.

When is a Vertical Laminar Flow Cabinet the Best Choice?

A vertical laminar flow cabinet is a clean bench providing a contamination-free area to handle lab samples, products, and other specimens. Vertical systems are designed to pass the HEPA-filtered air downward along the working area.

One important characteristic you need to consider is that laminar flow cabinets are suitable for non-hazardous products that are safe for an operator to inhale. There are limitations in terms of personnel protection. These devices ensure sufficient protection for samples during experiments, inspection, assembly, etc. However, they do not protect people operating the cabinet and everything else outside of the enclosure.

Laminar flow hoods don’t let in contaminated air from outside the hood, but the airflow from the inside is eventually vented into the room. So, if you need a more comprehensive type of protection, for example, when working with hazardous materials, consider other types of equipment.

You can use laminar flow hoods when:

- The task requires clean, particle-free air quality;

- There are no harmful materials involved;

- You need to protect the product but not the user or ambient environment.

Laminar flow systems are utilized in different industries where it’s crucial to keep the working environment ultra-clean and with no biological and particulate contamination. Examples include medical, pharmaceutical, scientific, and electronics fields. Here are some tasks that laminar flow hoods can be used for:

- Preparation and supply of sterile pharmaceutical products

- Production and validation of medical devices

- Cell culture experiments

- Preparing and pouring bacterial growth media

- Quality control and sterility testing

- Electronic and optical assemblies and systems

When to Choose a Biological Safety Cabinet

Biological safety cabinets are enclosed containment devices equipped with HEPA filter(s) to protect users, products, and the environment from hazardous materials. They are designed to remove potentially dangerous biological agents before the air is drawn outside. As a result, all micro-organisms, viruses, and bacteria are kept inside the enclosure. These cabinets are often used in laboratories to conduct research, clinical trials, and different kinds of experiments.

The term biosafety cabinet can only be applied to meet the Class I, II, or III specifications. It should follow international standards for biological safety in terms of their design, airflow pattern with the airflow velocity vectors, and their exhaust mechanisms.

The selection of a cabinet for safety against biological agents is based on what Biosafety Level it should be suitable for. Depending on what the user and the working space required for a specific task, you may need:

Class I – Solely for operator protection;

Class II – Operator, product, and environmental protection from materials with potential for aerosol transmission, associated with human diseases and primary hazards;

Class III – Operator, product, and environmental protection for specialized laboratory facilities dealing with deadly pathogens.

Class I BSC is characterized by outside air infiltration. It means that a studied sample will get into contact with contaminated air from outside, but the operator will not be exposed to it. This type has limited application options, which is why it is used less commonly than the other two types.

Class II biological safety cabinets should be used when you want multidimensional protection after the product is put onto the tray. These devices are constructed with an inward airflow (for operator safety), HEPA-filtered particle-free air forced downward (for product protection), and equally clean air going into the exhausting component (for environmental protection). It is a more widely used cabinet in medicine preparation, research, development, etc.

Class III biological safety cabinets have a maximum leak-tight construction. They have a fully closed front panel to eliminate personnel exposure to the product, airtight seals to keep the inside contamination-free as well as not let any air out, and a double-door pass to transfer the material from the nonsterile door to a sterile door inside. This type is used for very dangerous, life-threatening agents.

Summary

Major differences between these two types of equipment are primarily dependent on what a particular laboratory needs and what kind of protection a task requires. In this regard, laminar flow cabinets have the following characteristics:

- Product protection only;

- Unsuitable for biohazard or chemical hazards.

Biological safety cabinets can:

- Ensure product, personnel, and environmental protection;

- Sustain work with infectious agents.

If you are unsure which protection device is suitable for your needs, contact our specialists at Lamsystems. We will help you to determine your specific needs and select the right equipment.

Vertical Laminar Flow Cabinet

BAVnp-01-"Laminar-S."-1,2 LORICA

Article 2E-D.001-12

Dimensions(WxDxH),mm

1200х760х1752

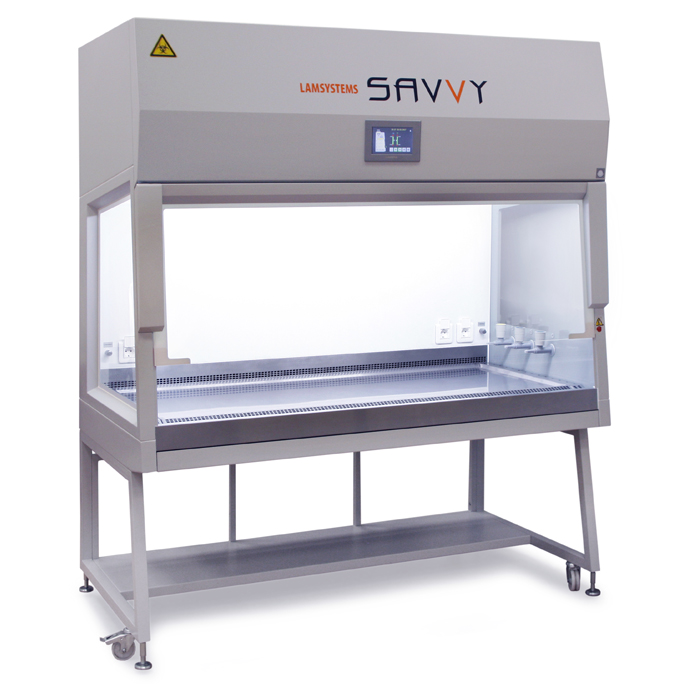

Biological Safety Cabinet Class II

BMB-II-"Laminar-S."-1,2 SAVVY SL

Article 2Е-В.008-12

Dimensions(WxDxH),mm

1200х810х2095