Biosafety Cabinets — Articles

BIOLOGICAL SAFETY CABINETS СLASS II

Biosafety Cabinets Сlass 2 (Microbiological Safety Cabinet Class 2) is for physical isolation of pathogenic biological agents (PBA) and microorganisms to prevent airborne infection of the staff and contamination of the air in the working room and to protect the environment...

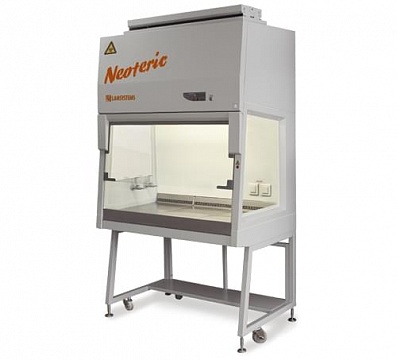

Biosafety Cabinet Manufacturer

Microbiological safety cabinets are specially designed in order to operate securely with contaminated and risky processes and materials that take place in labs. Bio safety cabinets are used to prevent environmental harm as a result of aerosols released through the hazardous practices carried out in the laboratory.

A biological safety cabinet is a ventilated cubicle that uses HEPA (High-Efficiency Particulate Air) to filter out all the pathogenic biological agents and microorganisms from the workspace environment and disseminates unpolluted air to clean up the environment.

Biosafety cabinets are commonly used in different laboratories, including medical and R&D laboratories. Based on the characteristics of each, biosafety cabinets are divided into three main classes: I, II, and III.

Purposes of biohazard safety cabinets

A biosafety cabinet has three basic uses; personnel, product, and environmental. Personnel protection is when the operator is secured from any hazardous accidents while through unsafe pathogens released from within the BSC. The person operating with a biological safety hood is protected through unidirectional air downflow and an air curtain in the work opening of the biosafety cabinets.

Product protection occurs when the processes, techniques, or experiments carried out within the laboratory are prevented from hazardous toxins and impurities. Environmental protection is the most significant purpose of a biosafety cabinet because it involves the protection of the entire workplace in which the person operates, and the processes take place. Cleaning up the workplace environment is a pre-requisite to perform the other two protection functions.

Classification and Certification process

When choosing a biological safety cabinet, classification is an important factor to consider. The standards of each type of cabinet are different depending on the sort of purpose that each one can perform. BSCs are classified into three types by a US-based organization known as Center for Disease Control and Prevention.

These classifications are carried out once all the biosafety cabinets have gone through proper certifications under National Sanitation Foundation International. The NSF has a responsibility to ensure that all BSCs are manufactured, installed, and used according to the minimum international standards required and they are classified according to their bio-containment and bio-safety levels.

Testing methods are also applied to the biosafety cabinets in accordance with the requirements of local standards to check whether they are used and maintained by the revised standards. Industries using these cabinets are given reminders at least a month or so before the expiry date of their cabinets and are asked to replace them with new ones and re-certify them at the time of installation.

Uncertified or expired biosafety cabinets are strictly prohibited for use in labs because of the infectious microorganisms that might be emitted through their operation.

Types of Biohazard Cabinets

There are three main classes of biosafety cabinets. They differ regarding their applications and the type of biosafety that they are capable of providing. A biosafety cabinet's protection level increases from level I to III. Class I is not suitable for samples but provides protection to users and the environment around them. The second class provides protection for samples, environments, and users but is divided under subtypes (the difference is between exhaust systems). The last, Class III or so-called glove boxes, is famous for giving the maximum protection. Our company provides all the three classes, and they have an industry-wide usage in both public and private sector.

Our biosafety cabinets are designed to provide the best possible risk protection in medical, education, as well as healthcare industries. Customers from a wide range of industries buy our biosafety cabinets because of the standards that we have maintained and the experts that are industrious in microbiology and make sure their integrity is not bargained at any cost.

Recommendations for usage

Being a supplier, it is our responsibility to guide you through the methods of operating our cabinets:

Safety cabinets must be operated in an environment with less traffic and without any draughts to avoid the spread of infections and diseases.

Safety cabinets must be operated in an environment with less traffic and without any draughts to avoid the spread of infections and diseases.

- UV lights must be turned off while fluorescent lights must be turned on.

- Turn on the air blower at the beginning

- Turn the cabinet on at least 5 minutes before starting work so that the contaminated air is removed from the cabinet

- Before using a biological safety cabinet for the first time, qualify its protection efficiency. Remember, cabinet qualification is required each time after its relocation

- The operator must be extremely cautious while carrying out all the processes.

- In a biosafety cabinet, the operator should wear a lab coat and long gloves.

- All contaminated things must be separated from clean materials in the lab so that they are not mixed up.

- Locate all the tools and materials as far from the work opening as possible but make sure the rear air grille is not closed

- Procedures that disrupt the operation of safety cabinets such as constant movement of operator's hands and excessive moving of material shall be avoided entirely.

Regular disinfection of a biosafety cabinet is essential because sterilization provides greater safety for materials, workers, and the environment. However, while decontaminating BSCs, some serious precautions need to be taken. For instance, you must always wear personal protective equipment (PPE) when sterilizing cabinets’ surfaces. PPE should at least include a laboratory coat, special gloves and long pants. Eyes must be protected as well. It is also highly recommended to protect your feet by wearing closed-toe shoes.

In case you have been working with highly infectious substances, your biosafety cabinet must be sterilized before you change HEPA filters or move the cabinet. No additional work can be done until the BSC is decontaminated. Typically, the disinfection of a biosafety cabinet is performed by third parties who use vaporized hydrogen peroxide, chlorine dioxide, or formaldehyde.

These recommendations apply to the regular sterilization of most biosafety cabinets. Before carrying out such a procedure for the first time or for specific disinfection procedures, it is advised to refer to the manufacturer’s operation and maintenance manual for additional instructions.