BMB-II-"Laminar-S."-1,2 NEOTERIC (221.120) Class II Biological Safety Cabinet

Application

- Physical isolation (containment and controlled removal from the work zone) of pathogenic biological agents (PBA) and microorganisms to prevent airborne infection of the staff and contamination of the air in the work room and laboratory environment;

- Minimization of risk of contamination and cross-contamination of the product;

- The cabinet neither protects from toxic chemicals and radionuclides nor contains work agent odors;

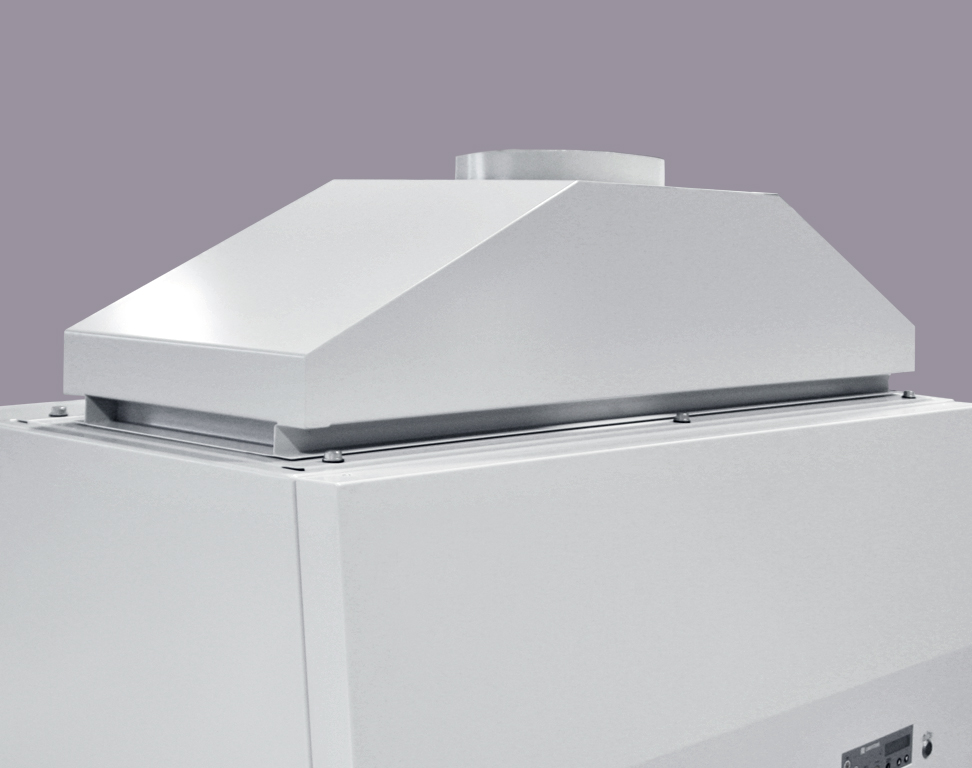

- Possibility to work with small amount of toxic chemicals and radionuclides as well as to remove work agent odors in case of mandatory connection to an active exhaust system using an exhaust hood supplied upon customer’s additional request;

- The cabinet is used to equip individual work places in medical, pharmaceutical and other institutions working with pathogenic biological agents and microorganisms.

Additional options

BMB-II-"Laminar-S."-1,2 NEOTERIC (221.120) Class II Biological Safety Cabinet

Application

- Physical isolation (containment and controlled removal from the work zone) of pathogenic biological agents (PBA) and microorganisms to prevent airborne infection of the staff and contamination of the air in the work room and laboratory environment;

- Minimization of risk of contamination and cross-contamination of the product;

- The cabinet neither protects from toxic chemicals and radionuclides nor contains work agent odors;

- Possibility to work with small amount of toxic chemicals and radionuclides as well as to remove work agent odors in case of mandatory connection to an active exhaust system using an exhaust hood supplied upon customer’s additional request;

- The cabinet is used to equip individual work places in medical, pharmaceutical and other institutions working with pathogenic biological agents and microorganisms.

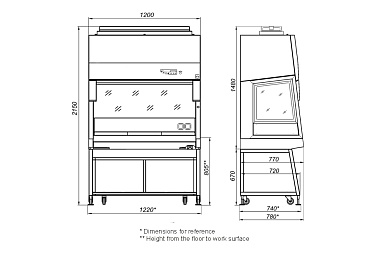

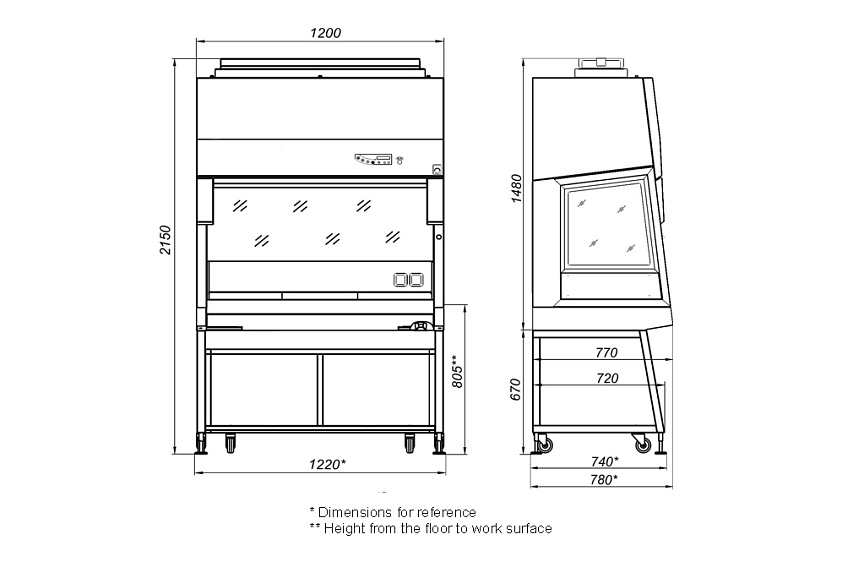

Main parameters and dimensions

Microbiological safety cabinet BMB-II-“Laminar-S.”-1,2 (221.120) NEOTERIC Class II

| Article | 2Е-В.001-12 |

| Maximum dimensions of the cabinet /WхDхH/* (dimensions without stand are in parenthesis) , mm | 1200х770х2150(1490) |

| Maximum dimensions of the stand /WхDхH/*, mm | 1195х720х670 |

| Dimensions of the cabinet assembled with stand and exhaust hood** /WхDхH/,mm | 1200х770х2355 |

| Maximum net weight of the cabinet assembled with stand, kg | 230 |

| Input power without built-in electric sockets, W | 180/110** |

| Maximum allowed load on the built-in electric sockets, W | 1000 |

| Clean air inflow capacity, m3/h | 795-817 |

| Exhaust air capacity, m3/h | 333-378 |

* dimensions do not account for outstanding supports

** The power consumption with newly installed uncontaminated HEPA filters.

MAIN CHARACTERISTICS

| Installation work chamber air cleanliness class for suspended particle (aerosol) concentration as per ISO 14644-1 | |

| -for particles of 0.5µm and more | ISO 5 |

| -for particles of 5.0µm and more | ISO M (20; ≥5µm); LSAPC |

| Class of the cabinet as per EN 12469 | II |

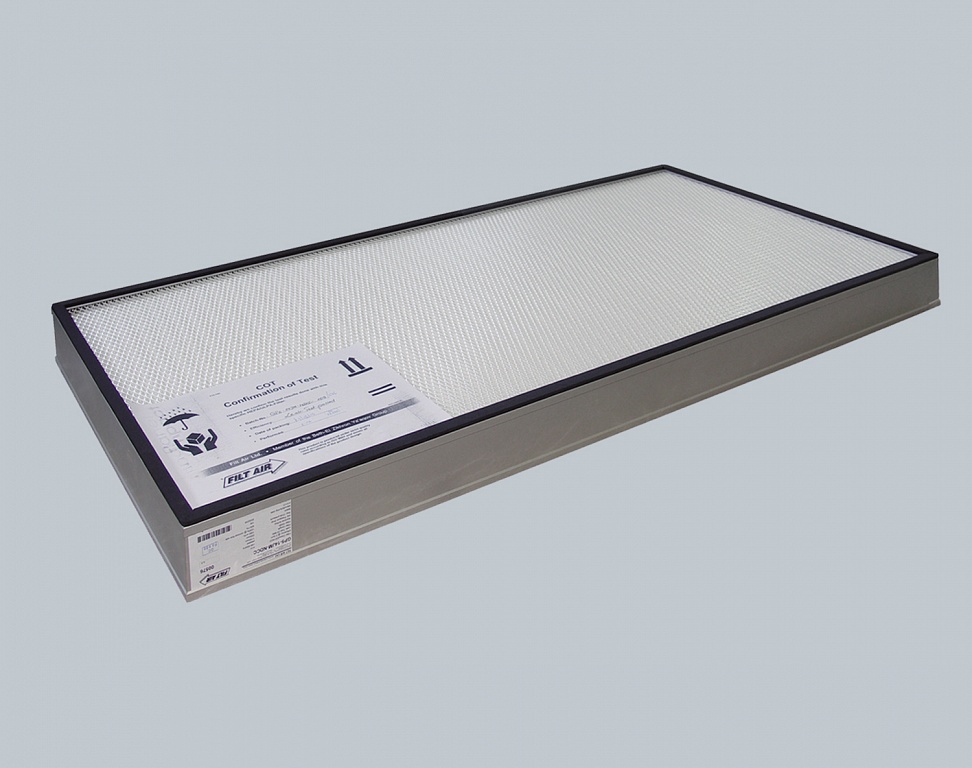

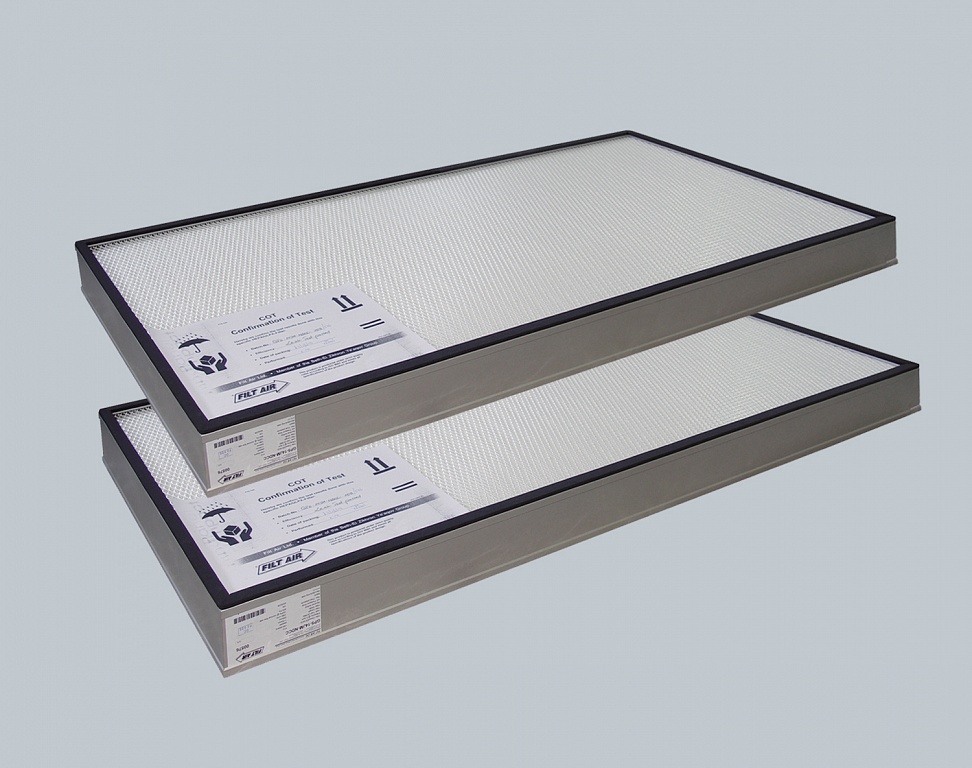

| Class of HEPA filters as per EN 1822-1 | H14 |

| Average velocity of the inflow though the working opening, mps | 0,47±0,03 |

| Average downflow velocity in the work chamber, mps | 0,35+0,01 |

| Minimum illumination of the work zone (integral value determined along the whole area of the work zone), lux | 1000 |

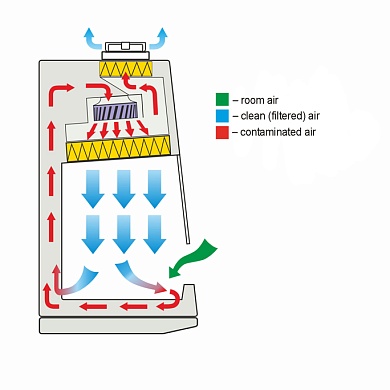

| Air recirculation, % | ≈70 |

| Maximum noise level at 1 m distance from the cabinet | 55* |

* level of noise at Main Operation mode measured as per DIN EN ISO 11201:2010 in free sound field over the sound-reflecting surface (noise level in real operating environment depends on the dimensions of the operating site, cabinet’s location as well as and on the total background noise and may vary by 3-4 dB(A)). Indeterminacy: k = 2 dB(A).

Dimensional drawing

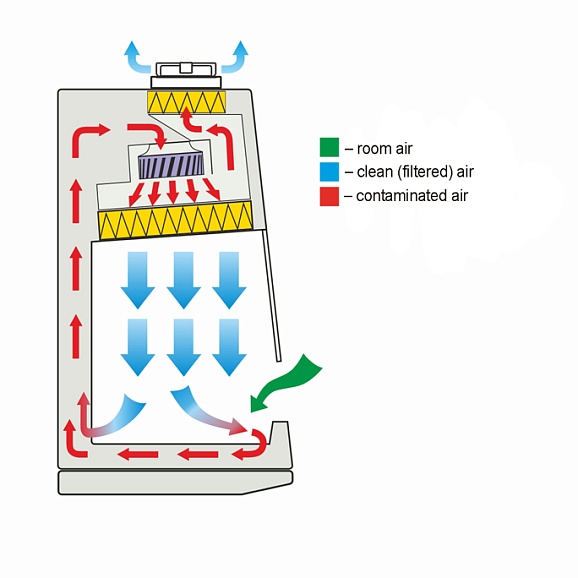

Air flow scheme

Standard Configuration

Work Chamber

- hinged front sash made of laminated safety glass; opening, closing and upholding is carried out by gas springs;

- damper against front sash closing impact;

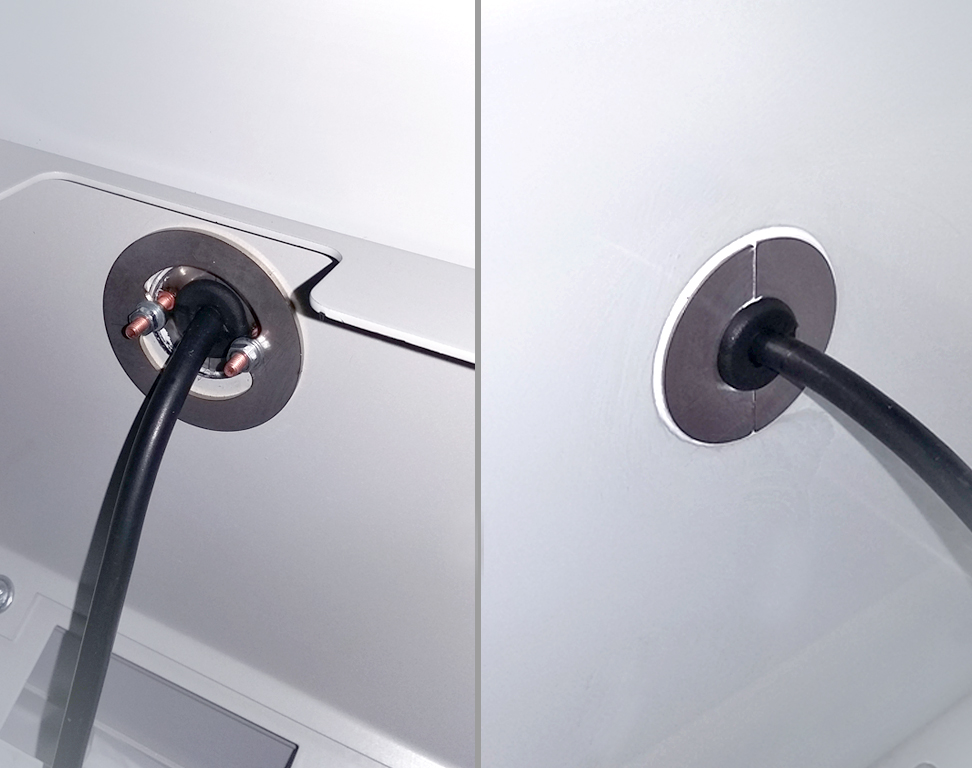

- side windows made of tempered glass: with tap ports on the left, solid on the right;

- slanted front surface of the cabinet;

- work chamber lighting – fluorescent lamp;

- two electric sockets in the work chamber (in the right part of the rear wall);

- airflow laminarization screen made of polymer micromesh;

- three-section tabletop made of stainless steel (AISI 304);

- work chamber tray made of stainless steel (AISI 304);

- tabletop reinforcements (3 pcs.);

- tabletop supports (2 pcs.);

- removable armrest made of stainless steel (AISI 304)

UV Unit

- pullout (when inoperative, is stored outside of the work chamber under the tabletop);

- metal grille protecting the UV lamp;

- dampers against any impact upon lowering the work opening screen.

Supply and Exhaust Air Filtration System

- supply air coming into the work chamber is cleaned by supply HEPA filter H14;

- exhaust air coming out of the cabinet is cleaned by exhaust HEPA filter H14.

Control System Components

- microprocessor control system;

- pushbutton control panel with LCD screen;

- electromagnetic reader and electromagnetic access keys;

- airflow sensors;

- front sash and UV unit position sensors;

- individual fuse for power supply to the main functions of the cabinet (fan, lighting, UV lamp);

- individual fuse for electric sockets of the work chamber;

- removable power cord with holder

Testing and Adjusting Components

- exhaust opening balancing baffle for airflow adjustment;

- built-in outlet for sampling the air upstream of HEPA filters for their integrity testing.

Stand

- frame stand with footrest;

- caster wheels for cabinet relocation;

- screw supports for cabinet fixation at operating site.

Additional options